ABOUT THE AUTHOR

Abraham García - Architect, Jr. Project Leader

“I think that the modular construction system is a clear example of how construction processes evolve and improve over time, demonstrating that architecture adapts to the time and space in which it is developed.”

The industry associated with architecture is always seeking to optimize and improve construction processes with the technological tools available, hence the idea of designing buildings whose elements are manufactured in one place and assembled in another. The above allows the architectural work to be completed through the unification of its parts where each of them, through a planning exercise, are integrated to satisfy the spatial needs of the users. This method provides benefits in quality and construction times. , costs and several other items.

What is Prefabricated Modular Architecture?

We are talking about a construction system with prefabricated modules, with joints and preparations focused on assembly, whose objective is to accelerate and make the building construction process more efficient. Below, I describe different methods of prefabricated architectural construction that have been evolving and improving over time, each one is differentiated by the type of material used, the method of transportation and the on-site preparations necessary to consolidate the construction.

Different types of prefabricated modular system applications

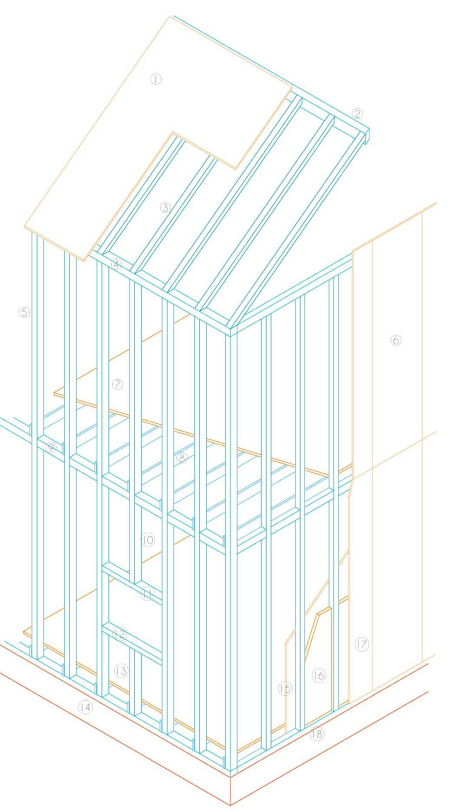

1. Balloon Lattice

In its beginnings, the prefabricated construction system was known as “Framework” over time, construction variations emerged, such as: Balloon Frame or “Globe Frame” this system consisted of the union of linear wooden elements joined together by nails, generating frames. Once the framework was assembled, they were covered with wooden boards nailed to the structure. For the enclosures, they were mostly executed on the ground and were later elevated for placement.

Alba.L. (2019-2020). Constructive axonometric of Balloon Frame system. Constructive analysis of current modular architecture intended for single-family homes.

2. Platform Network

The building rises floor by floor, in such a way that the mezzanines interrupt the continuity of the structure. This change is due to the great difficulty in finding elements of sufficient length and, subsequently, transporting them.

Alba.L. (2019-2020). Single-family home developed with a platform system. Constructive analysis of current modular architecture intended for single-family homes.

3. Metal Lattice

It is a derivation of the Ballon Frame, using thin galvanized steel profiles to replace wood. The linear elements are joined using self-drilling screws, so the simplicity of assembly is maintained. The prefabrication of the profiles allows them to be machined at the factory, which greatly facilitates the work of hydraulic and electrical installations, further reducing time on site. Another point to consider regarding this system is the recyclability of its material, which allows it to reduce its environmental footprint.

Single-family home developed with a metal framing system. Constructive analysis of current modular architecture intended for single-family homes. (2019-2020).

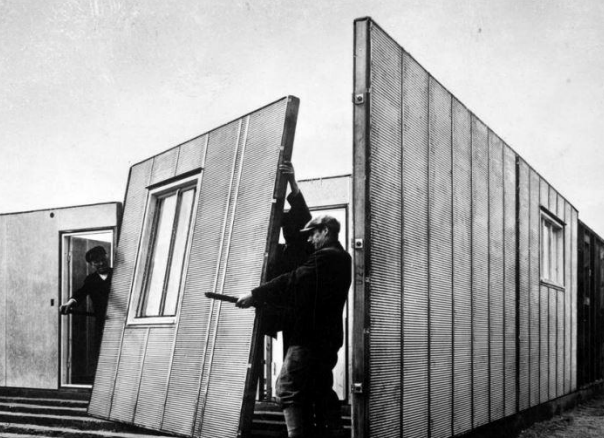

4. Panel System

The panels function as both structure and enclosure. In some specific types, horizontal structures are not necessary, so it is the panels themselves that support the building. The components are manufactured in a workshop and some may incorporate elements such as carpentry or the necessary installations. Within this system, structural insulating panels can be used, formed by an insulating foam core located between two structural faces. Counter-laminate panels use layers of sawn wood glued in such a way that the fibers of two adjacent layers are oriented perpendicularly. They usually consist of 3, 5 or 7 layers, which can be of different thicknesses and/or woods depending on the needs of the work.

Assembly of panels from The Copper House, “Houses that Grow”, Berlin. (Gropius, 1931)

5. Precast Concrete

At first, this type of panels consisted of a single solid sheet of concrete, but, over time, they have evolved, incorporating insulating material such as extruded polystyrene that improves their thermal characteristics.

Placement of prefabricated concrete panel with hole and carpentry. (Tarres, 2017).

6. Manufacturing by 3D components

Here reference is already made to the construction of a building using almost finished modules: finishes, installations, walls, mezzanines, carpentry, etc. that are generated in a factory to be later transferred to the construction site. Work on site is reduced to a minimum, leaving only the joints and connections to services. Sometimes they can incorporate more complex elements such as stairs. Construction by 3D modules greatly reduces joint problems since most of them are executed in the factory, with great quality controls. On site, execution is simpler and faster, although transportation is usually more complex and expensive.

Housing module with enveloping faces. It left the factory completely finished, leaving only the foundation and service networks in progress. (Worldmetor, 2017).

Illustration made by Architect Arath Santos for Cafeína Design

Modular construction

General process of modular construction

Although there are different ways to apply this system, we can conclude 4 common steps that are followed in prefabricated construction:

- Project design

- Manufacturing of the modules

- Transportation of elements

- Final assembly

Advantages of modular architecture

- Reduces execution times.

- Simplicity of assembly.

- Allows installation of buildings in places with difficult access.

- Quality is guaranteed by millimeter supervision and assembly standards.

- Savings in construction and maintenance costs.

- Industrial architecture uses materials such as expanded polystyrene, 100% recyclable and with a low carbon footprint, this means that the greenhouse gases emitted when carrying out these construction processes are greatly reduced, counteracting the acceleration of current global warming.

The BIM methodology applied to the modular construction system

Modular architecture is known for being simple, because it is possible to add modules where necessary and each module fits into the building without having to make adjustments to the overall design. At the same time, its complexity lies in the fact that each module must fulfill multiple independent functions such as maintaining strict limits on the shape and size of the module.

In this area and with the powerful rise of digital technologies, different alternatives have been developed in the design and development of architectural projects, improving and integrating processes related to the entire life cycle of a building from its design, construction and management of plays. Here the BIM methodology is applied, which consists of organizing work collaboratively and simultaneously between all the agents involved, thus reducing uncertainties or inefficiencies that can generate deviations in deadlines, cost overruns or changes in quality, such as including materials. out of stock or not taking into account the environmental impact. At Cafeína Design we are fully immersed in the implementation of the BIM methodology, applying in each project the best collaborative design tools and strategies to implement them in conventional systems or through prefabrication.

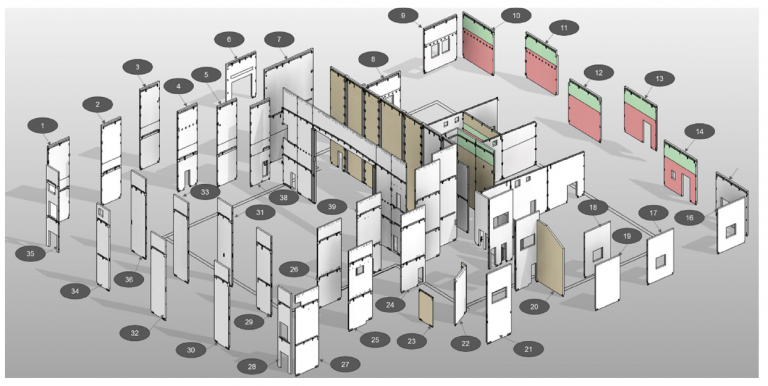

Kit of parts of tilt-up panel by BIM platform, Autodesk University, Integrated BIM Workflows in Modular Prefabricated Construction: Concept to Fabricate

Conclusion

Modular construction has been in constant evolution and improvement, which has led to innovating the system from the prefabrication of the elements necessary for its assembly to the 3D printing of a complete previously designed building, for this the methodology benefits from the support of appropriate software for the simulation analysis of construction sequences and programming of construction times offered by programs with BIM application, allowing the best planning of the use of its variations, taking the needs of the user and the environment as a priority. It is a construction system with great expectations for the future.

Want to know more about this topic?

Contact us